Welcome to the Era of Cloud-based CAD Design: Where Innovation Meets Execution

From simple hand-drawn sketches to advanced cloud-based simulations, CAD design has evolved in ways that seemed impossible not long ago. In this article, I invite you on a journey through my design experiences, from the first steps in creating modern devices to a large metallurgical overhead crane.

First steps

A few years ago, during changes in my professional path, I was faced with the challenge of deciding on the direction I wanted to follow. I decided to direct my interests towards designing modern devices of various types. It is a fascinating activity that not only provides a lot of satisfaction, but sometimes also brings tension during tests and commissioning of newly created devices.

To implement my plans, it was necessary to decide on the direction I would follow and the choice of tools. Nowadays, traditional pieces of paper and a pencil sometimes turn out to be insufficient. I realized that it is best to quickly transfer the ideas that arise in the designer's head into three-dimensional models, which makes them easier for both team members and clients to understand.

My brother, who works in IT, was helpful in this regard. He proposed that we do everything in the "cloud" - as a solution with numerous advantages, both effective and economical.

We chose solutions based on cloud technology, placing great emphasis on working in a distributed team operating from different locations:

- Google: email, meetings, drives, office applications

- Onshape: 3D design

- Skyciv: calculations of beam models

- Swiftcalc: calculation sheets

Additionally, we use many smaller applications that support our daily work.

Sample project

In our daily work, we rarely come across projects with a small number of elements; models consisting of main assemblies of machines and devices often contain hundreds or even thousands of various components. Another challenge we face in the design process is the significant number of changes that occur at various stages. This poses a significant challenge for CAD systems.

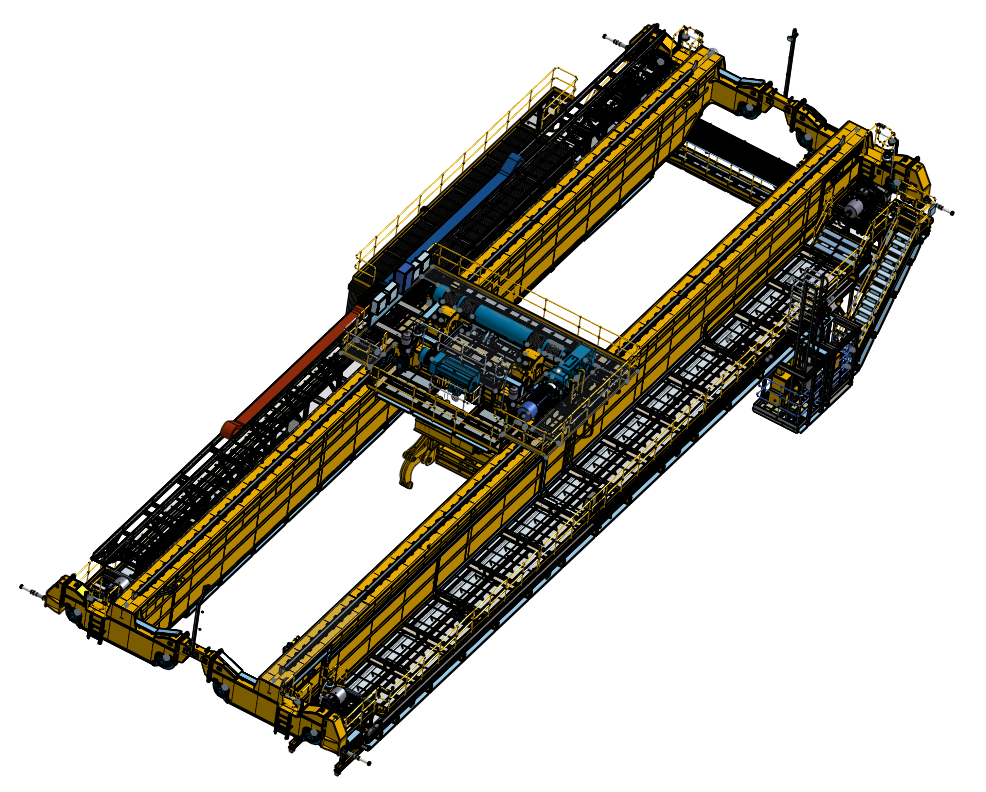

An example of such a project is the construction of a heavy clamp crane, designed to work in difficult conditions when transporting hot steel plates.

Crane parameters:

Main lifting capacity in clamps 70t (weight of clamps 20t - total weight lifted approx. 90t)

Crane span 39.5m

Lifting speed 15 m/min

Winch travel speed 60 m/min

Crane travel speed 120 m/min = approximately 7.2km/h

Cab travel speed 20 m/min

Total weight of the crane 255.5 tons

Power of installed electric motors approx. 600 kW (S3, KT +80℃)

Work Intensity Group A8 - maximum

Operating temperature +80℃

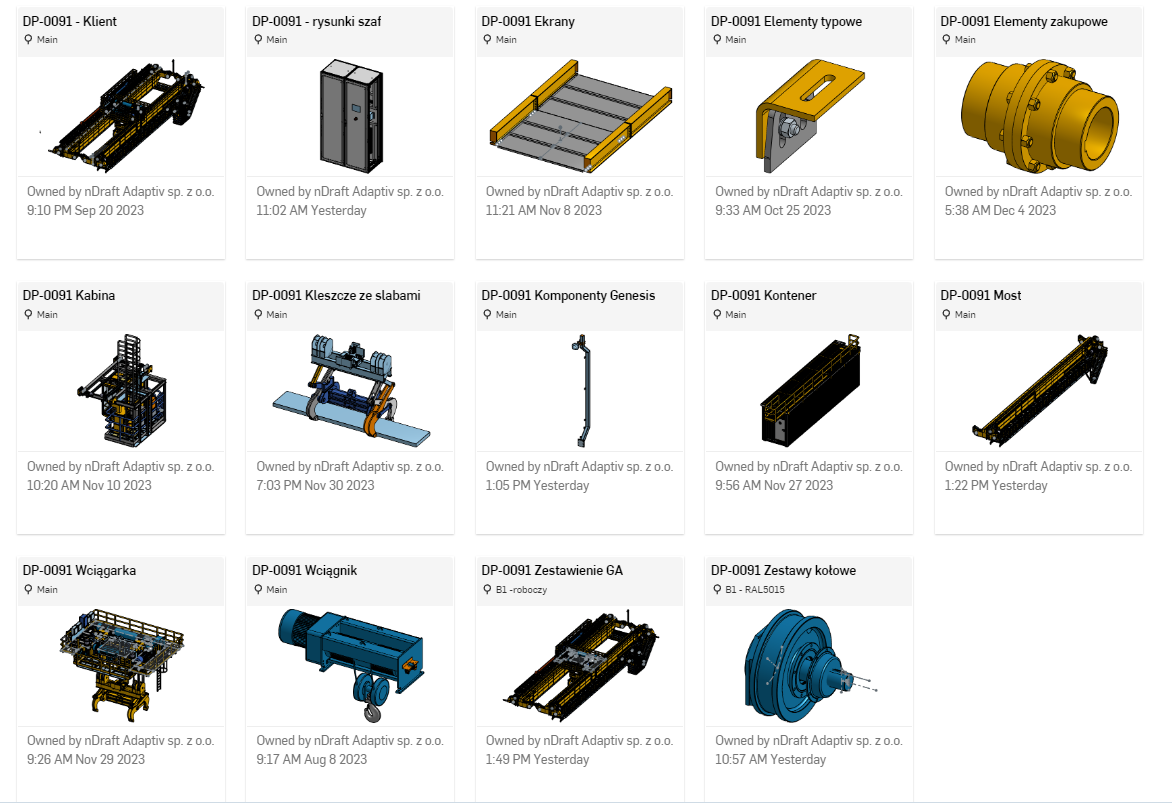

Having previous experience with large models and using suggestions from the Onshape manufacturer, we decided to divide the project into 11 separate projects (Onshape - Documents). These projects are then linked to the main schedule and also include additional supporting projects (Onshape - Documents), such as a project with purchase elements or projects with calculations. This division significantly affects the speed of loading models and increases the transparency of the structure of the entire project.

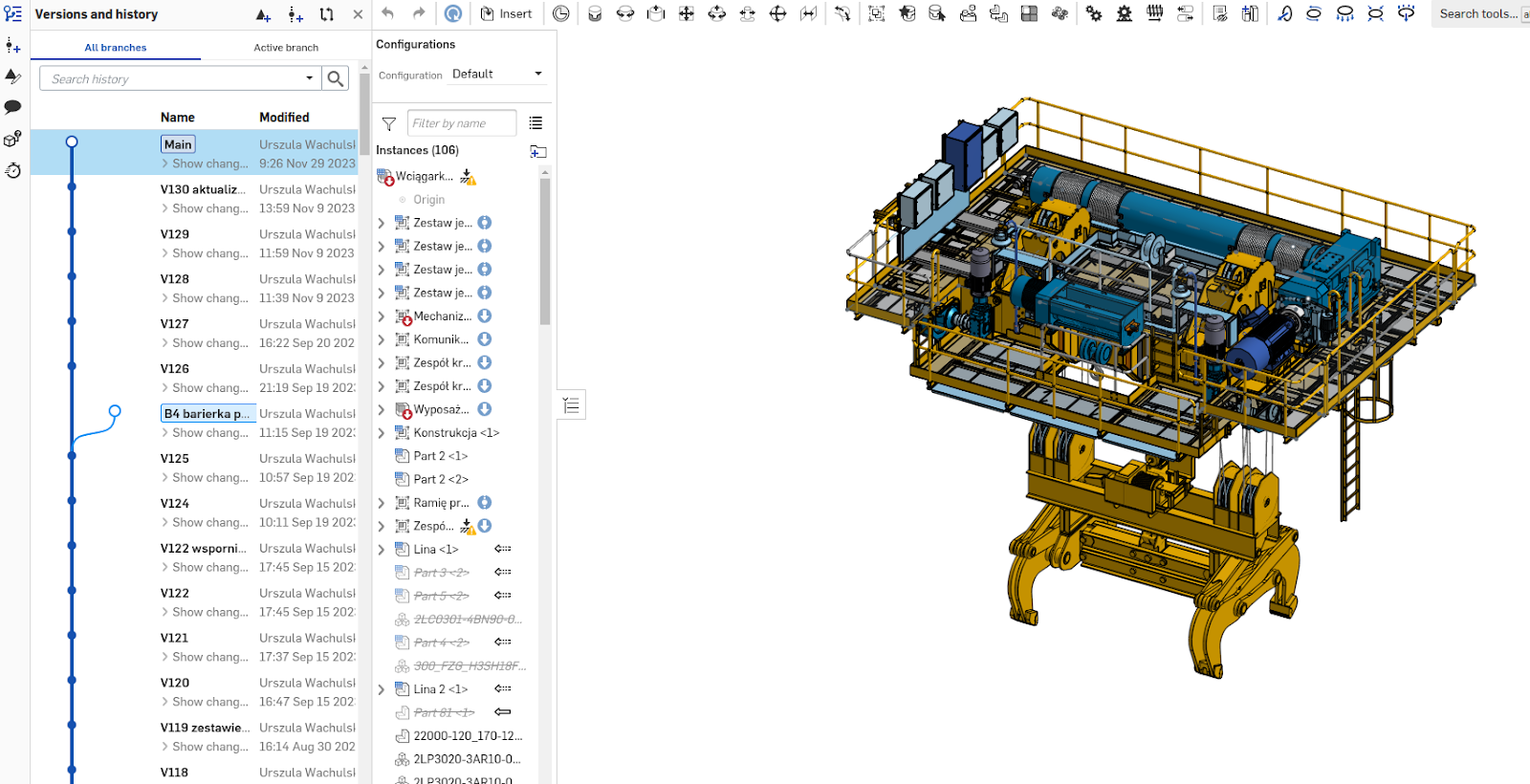

Additionally, a conscious approach to changes in the project is important, and the division into different projects makes their management easier. The project was implemented for a long time, after each release of drawings, a new version of the project was made (Onshape-document). As is often the case in design, various solutions were tested - everything is in the system and can be viewed at any time.

For more information about documents and effective change management, please visit the official website of the manufacturer Onshape.

Statistics

Some numbers about the project:

1. Number of drawings made: 421, most of them in A1 format. More than half of the drawings are in several A1 formats

2. W main assembly:

- Total number of parts - 37194

- Total number of subassemblies - 1120

- Number of unique parts - 3246

- Number of unique subassemblies - 341

3. Number of versions in project (documents):

- Crane bridge - approx. 356 versions

- Winch - approx. 130 versions

- Main assebmly - approx. 37 versions

As you can see, the model is very large, but Onshape handles it efficiently. Loading the main summary takes about 30-40 seconds. It is worth noting that in the case of cloud-based solutions, a stable Internet connection plays a key role. Of course, for larger models it is necessary to have a faster connection and a computer capable of efficiently processing such large models. However, currently most users have access to appropriate resources (even though it was different during my project).

The advantage of working in the cloud is flexibility when it comes to choosing an operating system. Personally, I have always preferred Linux, but due to the nature of the programs used, I was forced to use Windows. Now, thanks to working in the cloud, I have freedom of choice, and I have been working on Linux for many years. Combined with the lightweight XFCE graphical environment, I achieve very good results even on an older computer and work is comfortable.

Connection parameters and the computer on which the tests were performed

- Internet: fiber optic 600/150 Mb/s

- Computer:

- Model: Asus "Republic of Gamers" ROG GL502VM

- Processor: Intel Core i7 siódmej generacji

- Graphic card: Nvidia GeForce GTX 1060

- Resolution: FullHD

- Operating system: Linux Mint 21.2 with XFCE desktop environment version 4.18.1

A great advantage of the Onshape system is the ability to make models available to the client, allowing him to comment on them at the design stage and use them during production. You don't need any special software to use this tool - just a regular browser on a standard computer, tablet or even smartphone. Of course, with such large models, it is recommended to use a computer with higher capabilities, although it is not necessary to have dedicated graphics hardware.

The ability to view three-dimensional models significantly supports the production and assembly process. This is an aspect that is of great interest to both our customers and ourselves during the production phase.

Preparation of documentation

Onshape allows you to make drawings both from a "live" model and from saved - approved - versions. The second solution works great for more complex models. First of all, adding new views and opening ready-made drawings takes less time. This works especially well when the rest of the team continues to work on models of interacting elements.

Onshape has introduced a number of improvements in creating drawings of devices consisting of many parts - the already mentioned drawing from a saved version of the model and the ability to simplify less important details in general summary views. With our "mares" (larger drawings are 4-7 A1 sheets), these solutions are barely sufficient - by turning on the update, you can easily make yourself a cup of coffee or do a short exercise - and several times we have used the "help" which responds "right away" and solves most problems on the same day.

Onshape is constantly evolving and updates are made available regularly. Due to the nature of the cloud solution, we do not have to update the system separately - we always use the latest version, which translates into work improvements and the addition of new functions. This is beneficial because updates are automatically implemented, eliminating the need to manually adjust the software.

Summary

As you can see, working with Onshape and other CAD tools in the cloud is not only the future of design, but also the present, which brings tangible benefits. These solutions allow for smooth progress through subsequent stages of the project, from concept to implementation, regardless of the complexity or size of the machine. In a world where technological innovations are evolving day by day, we are witnessing how the flexibility and availability of the cloud are transforming our approach to engineering and manufacturing.

I encourage anyone who is still hesitant to take the leap into cloud CAD design to consider the possibilities that Onshape offers. Whether you're an experienced engineer or just starting your design journey, the cloud has something valuable to offer. Visit Onshape's official website to learn more and start your own design revolution.

The cloud is not only a place to store data, but a space where our creativity and innovation can develop without limits. Let our joint projects, like the overhead crane described above, soar high - not only in the digital cloud, but also in our aspirations and achievements.