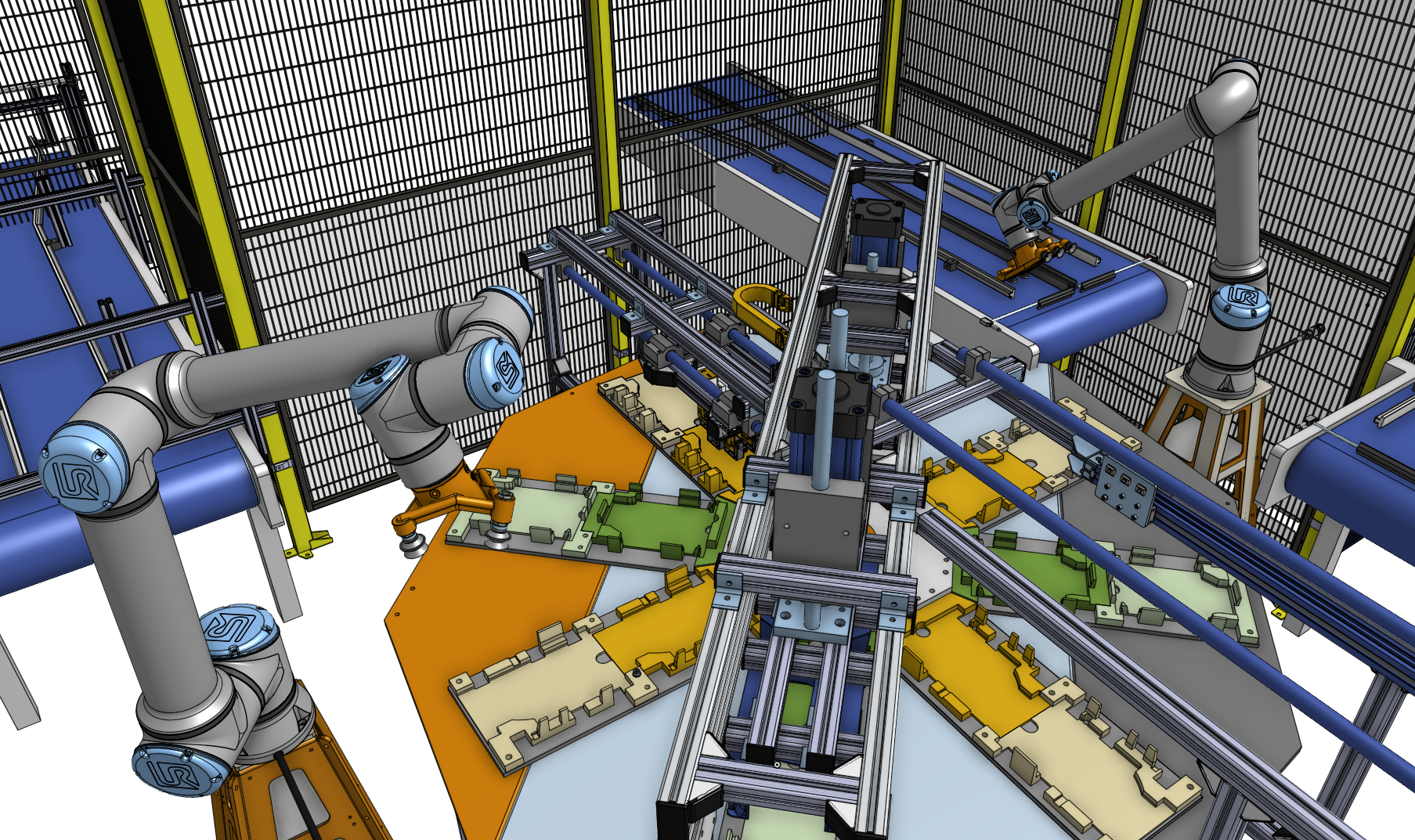

Robotic Pick&Place stations based on a collaborative robot

The task of Pick and Place stations is to pick an element and put it in a specific place, where subsequent production processes usually take place. Elements are most often taken from various types of conveyors, and the strict times of the production cycle require the simultaneous collection of more than one detail.

Depending on the production stage, cobots transfer the details from the conveyor directly to the technological machine or pick up the product from the machine and put it on the conveyor. In the case of long technological processes, it is possible to ensure two-way transfer of elements using only one cobot. We will be able to meet the process efficiency required by the customer with the use of grippers specially designed and dedicated to a given process, which can pick up several pieces at the same time or be adapted to carry different details.

With higher cobot speeds, we equip the station with additional radars that will slow down the robot's work when a human appears in the work zone. If the production process and its characteristics make it impossible to slow down the work, we use appropriate fencing to separate the staff from the high-speed cobot.