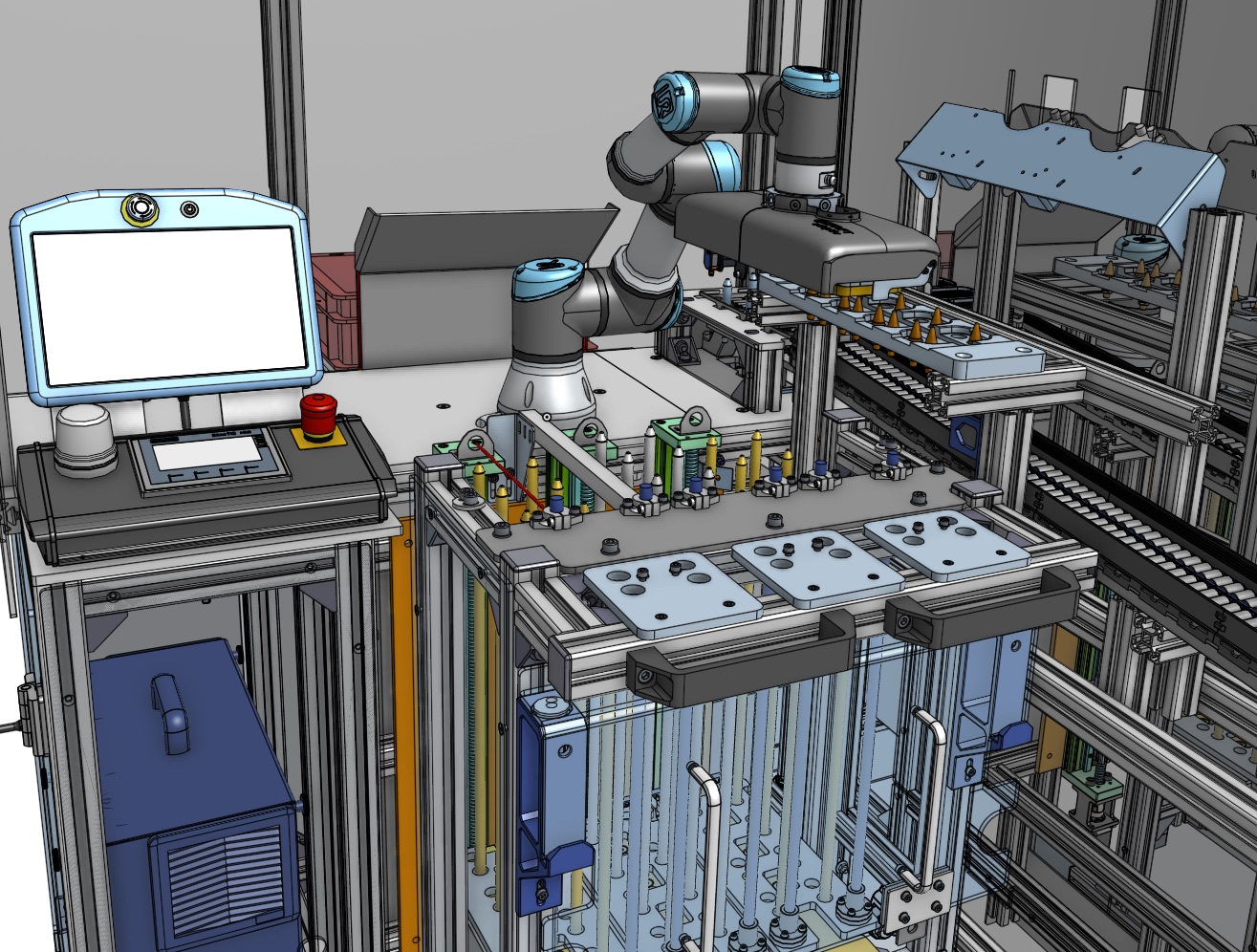

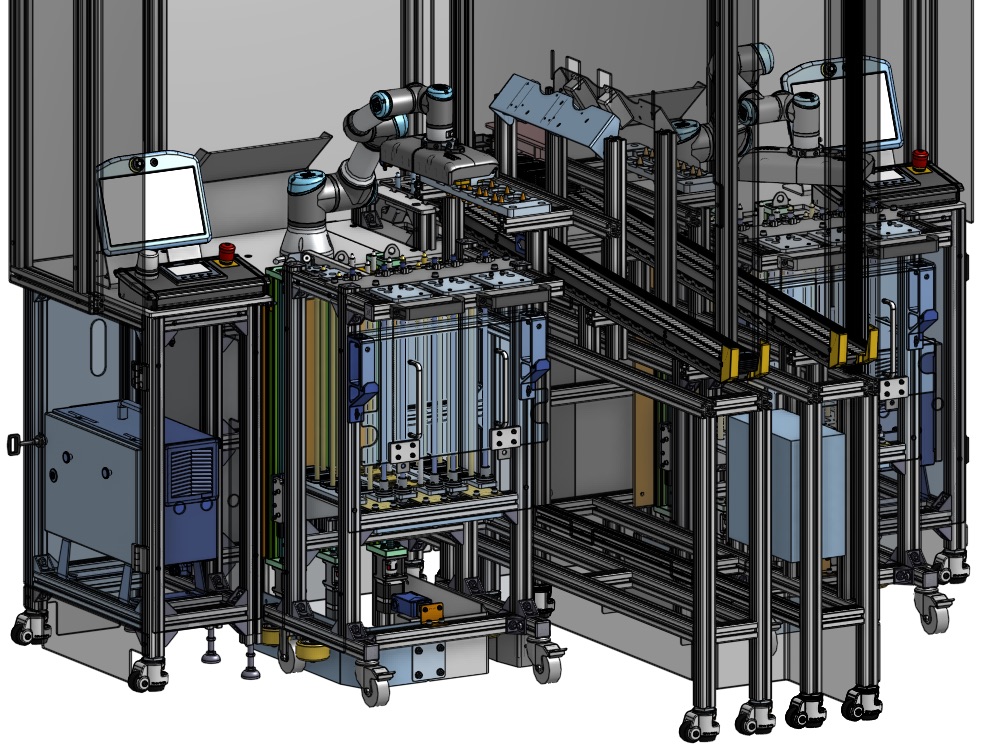

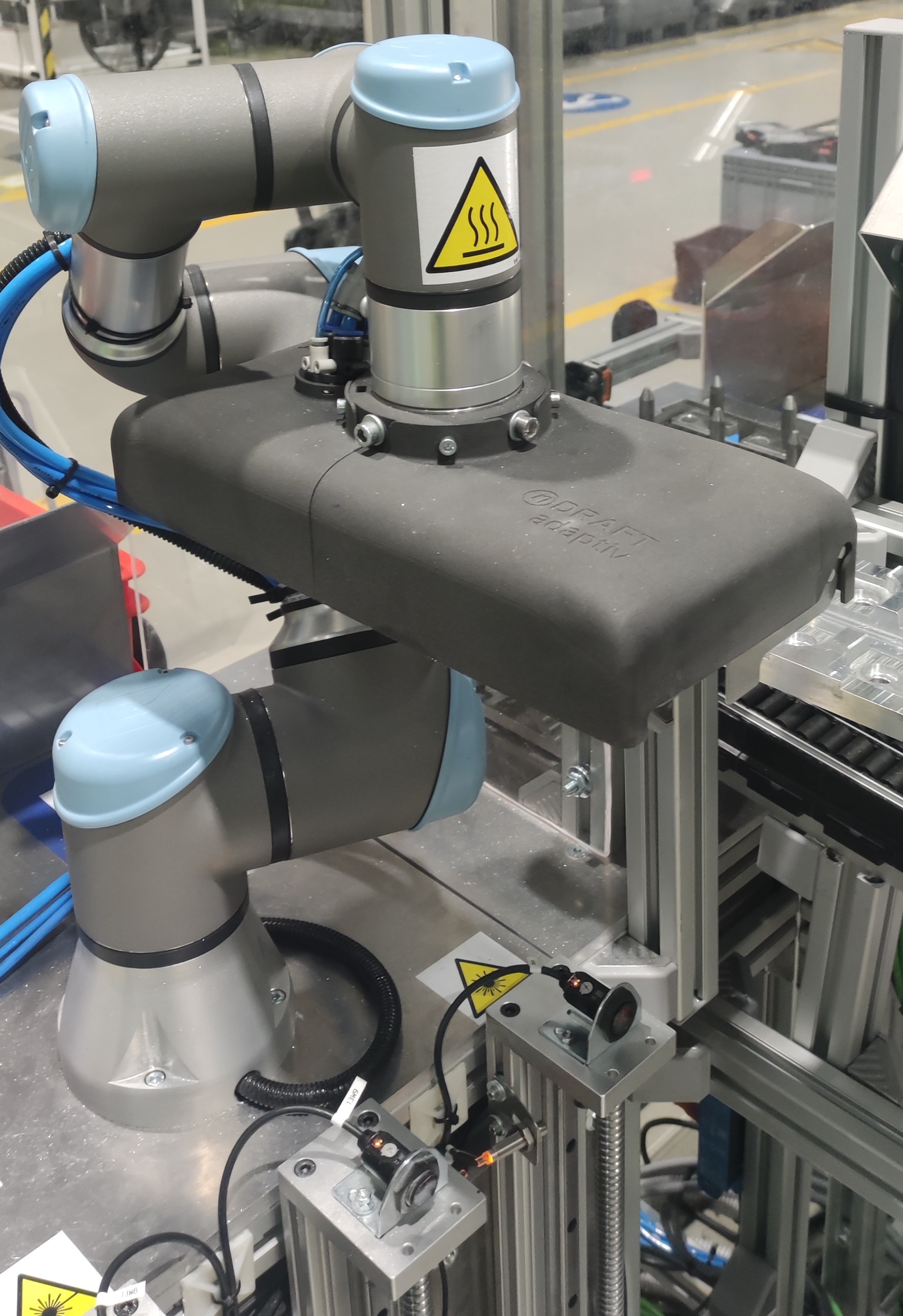

Assembly station with collaborative robot and quality control

Besides simple operations related to the movement of elements by cobots, it is possible to use collaborative robots for tasks related to the assembly of elements. In addition, before assembly, we are able to check the correctness of the details used, i.e. whether correctly made details are used for assembly and are arranged in the right order. Elements to the station are delivered using various types of conveyors, special trolleys or standard containers. The cobot collects the appropriate elements, then the correctness of the details is checked using the vision system and the final assembly.

With higher cobot speeds, we equip the station with additional radars that will slow down the robot's work when a human appears in the work zone. If the production process and its characteristics make it impossible to slow down the work, we use appropriate fencing to separate the staff from the high-speed cobot.