A device for checking the correctness of thread execution

In many cases, we must be sure that the thread is correct, i.e. it allows the screw to be screwed in and has the appropriate accuracy class. This is especially important when the element must be mounted somewhere earlier and when screwing the screw into the threaded hole there is resistance that prevents correct screwing in.

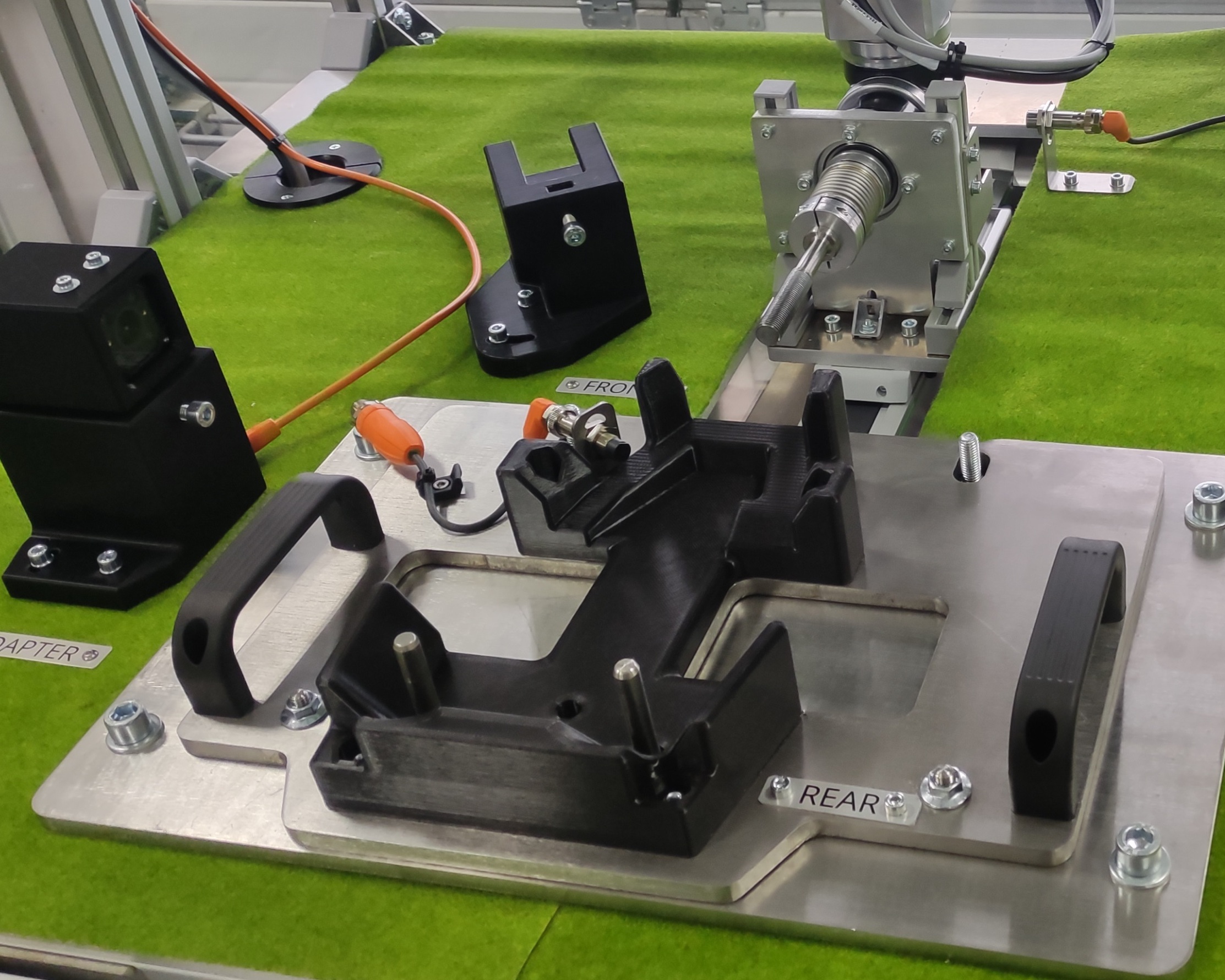

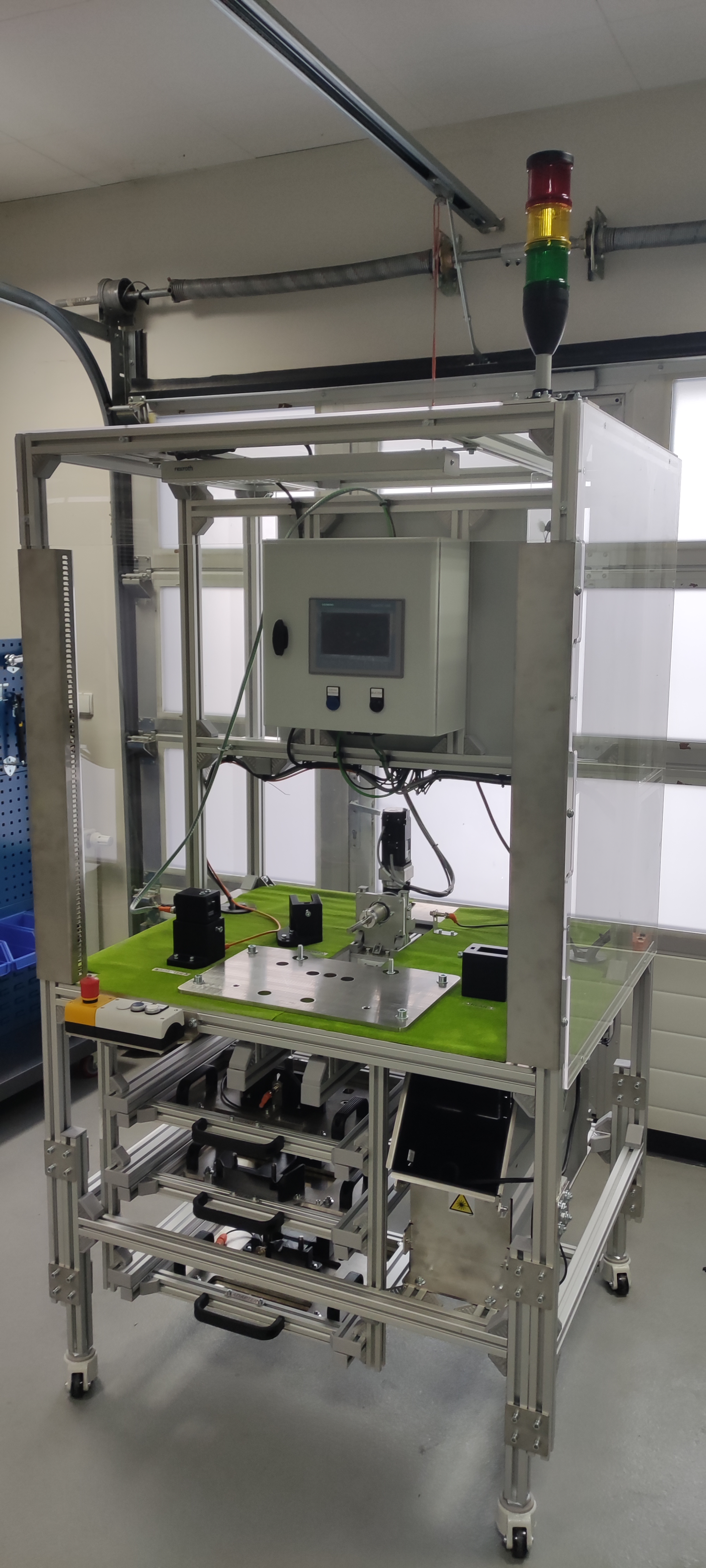

One of the simple ways to check is to check the thread with a manual gauge beforehand, but the problem arises when there are a lot of these elements and manual checking is lengthy. This is where a device that quickly screws and unscrews the gauge into the hole can come in handy. When jammed during screwing, it signals to the operator that the thread is damaged and the element should be re-threaded or withdrawn from further production.

The station can be adapted to several types of elements and quickly converted to another element. They can also be equipped with gauges of different sizes and test threads of various sizes. Also the direction of the thread is not a problem - whether right or left and whether metric or inch. The use of a PLC with servo drives ensures great freedom in programming the device in the future and quick adaptation of the device to new tasks.